Nanu inibalbulacavitation? makananu yang ilako?

Tianjin Tanggu Water-Seal Valve Co., Ltd

Tianjin,CHINA

ika-19,Hunyo,2023

Nung makananu ing tigtigan atin yang negatibong epektu keng katawan ning tau, deng mapilan a frequency malyari lang makasira kareng kasangkapan ning industriya nung ing control valve mapili yang masalese, atin yang mas maragul a panganib ing cavitation, na magdalang matas a ingay ampo vibration levels, a magresulta keng mabilis a pangasira da reng internal ampo downstream pipes ningbalbula.

Dagdag pa, ing matas a ingay keraklan magdalang vibration na malyaring makasira kareng pipe, instrumentu ampo aliwa pang kasangkapanBalbulakeng pamaglabas ning panaun, ing pangasira da reng sangkap, ing valve cavitation a sangkan ning pipeline system a prone keng seryosung pangasira. Ing pangasira keraklan manibatan ya keng vibration noise energy, accelerated corrosion process ampo cavitation a mipalabas keng matas a noise level ning maragul a amplitude vibration a gewa ning pamaglalang ampo pangabagsak da reng steam bubbles malapit ampo lalam ning shrinkage.

Agyang iti keraklan malilyari ya keng bolabalbulaat rotary valves keng katawan, malyari yang malyari keng makuyad, matas a pamagbawi kalupa ning wafer body part ning V-ballbalbula, tangibalbula ning parulkeng bandang lalam ning balbula nung ingbalbulamaka-stress ya keng metung a posisyun a prone keng cavitation phenomenon, na prone keng leakage keng valve piping ampo welding repair, ing valve ali ya suit para kening section ning linya.

Agyang nanu pa ing cavitation kilub ning balbula o king lalam ning balbula, deng kasangkapan king lugal ning cavitation mika maragul lang pangasira kareng ultra-thin a pelikula, springs ampong malating section a cantilever structures, deng maragul a amplitude vibrations malyari lang mag-trigger oscillations. Deng maralas a failure points mayayakit la kareng instrumentu antimo reng pressure gauges, transmitters, thermocouple sleeves, flowmeters, sampling systems Deng actuators, positioners ampo limit switches a maki springs mabilis lang magamit, ampo deng mounting brackets, fasteners ampo connectors maluwag la ampo mabigu la pauli ning vibration.

Ing fretting corrosion, na malilyari pilatan da reng mesira a bage a makalwal keng vibration, karaniwan ya kareng cavitation valves. Iti magproduce yang hard oxides bilang abrasive para mabilis ing wear pilatan da reng wear surfaces. Deng apektadung kasangkapan kayabe la reng isolation ampo check valves, dagdag pa kareng control valves, pumps, rotating screens, samplers ampo nanu mang rotating o sliding mechanism.

Deng matas a amplitude vibrations malyari la namang mag-crack ampo mag-corrode kareng metal valve parts ampo kareng pader ning pipa. Deng makakalat a metal particles o corrosive chemical materials malyari lang makakontamina keng media keng pipeline, na malyaring mika maragul a epektu keng hygienic valve piping ampo keng high purity piping media. E ya pu pwedi ini.

Ing pamaghula keng cavitation failure da reng plug valves mas komplikadu ya at ali ya basta-basta makalkula ing choke pressure drop. Ing karanasan sasabyan na na ing pressure keng main stream mibaba ya keng vapor pressure ning likidu bayu ing local vaporization ning lugal ampo ing collapse ning steam bubble. Deng mapilan a gagawang balbula sasabyan da ing premature eclipse failure kapamilatan ning pamagdefine keng initial damage pressure drop. Ing paralan ning gagawang balbula para magumpisa keng pamagpredict keng cavitation damage makabasi ya keng katutwan na deng steam bubbles mangabagsak la, a magdalang cavitation ampo ingay. Meyakit na ing makabaldugan a pangasira ning cavitation maiwasan ya nung ing makalkula nang lebel ning ingay lalam ne ning limitasyun a makalista lalam.

Ing sukad ning balbula anggang 3 pulgada – 80 dB

Ing sukad ning balbula 4-6 pulgada – 85 dB

Ing sukad ning balbula 8-14 pulgada – 90 dB

Ing sukad ning balbula 16 pulgada at mas maragul – 95 dB

Paralan para mawala ing pangasira ning cavitation

Ing espesyal a disenyu ning balbula para mawala ing cavitation gagamit yang split flow ampo graded pressure drop:

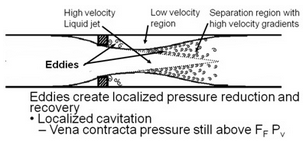

Ing "Valve diversion" yapin ing pamikawani ning maragul a danum kareng mapilan a malating danum, at ing dalan ning danum ning balbula dinisenyu ya bang ing danum dumalan ya kareng mapilan a parallel a malating pasbul. Uling ing dake ning sukad ning cavitation bubble makalkula ya kapamilatan ning pasbul nung nukarin ya daralan ing danum. Ing mas malating pasbul papalyarian nala deng malating bula, a magresulta keng mas ditak a ingay ampo mas ditak a pangasira nung datang ing pangasira.

Ing "Graded pressure drop" mangabaldugan yang ing balbula dinisenyu ya para mika adwa o maigit pang adjustment points a serye, inya imbes na ing mabilug a pressure drop ya keng metung a step, atin yang mapilan a mas malating step. Ing mas ditak kesa keng indibidwal a pressure drop malyari yang makapigil keng pressure keng shrinkage ibat keng falling vapor pressure ning likidu, inya sa't mawala ing phenomenon ning cavitation keng valve.

Ing pamisanmetung ning pamag-divert ampo ing pressure drop staging keng parehung valve paintulutan na ing mas masanting a cavitation resistance kapamilatan ning. Kabang magbayu ya ing balbula, mas matas ing pamagposisyun king control valve ampo ing pressure king inlet ning balbula (alimbawa, mas marayu king babo ning ilug, o king mas mababang katas), neng misan makalako ya kareng problema king cavitation.

Dagdag pa, ing pamagposisyon king control valve king lugal ning temperatura ning likidu, at uli na niti ing mababang presyur ning singaw (antimo ing mababang temperatura king gilid ning heat exchanger) makasaup yang mawala ing problema king cavitation.

Ing summary pepakit na ing cavitation phenomenon da reng balbula e ya mu tungkul keng degradation performance ampo ing pangasira da reng balbula. Deng pipeline ampo gamit keng ilug atyu la naman keng panganib. Ing pamagpredict keng cavitation ampo ing pamaggawa kareng paralan para mawala ya ing paralan para aiwasan ing problema ning mamasang gastus keng valve consumption.

Oras ning pamagpost: Jun-25-2023