Kabaldugan ning produktu

Ing malambut a sealing flangeDoble Eccentric Butterfly Valve(Dry Shaft Type) metung yang matas a performance a balbula a dinisenyu para keng eksaktung pamagkontrol keng danum kareng pipeline. Atin yangdouble-eccentric structureat metung a malambut a mekanismo ning pamag-seal, a kayabe ning metung a “dry shaft” a disenyu nung nukarin ing shaft makabukud ya king medium a danum. Ing configuration ayni makasiguradung mapanalig a pamag-seal, mababang torque a operasyun, ampo pamaglaban keng corrosion ampo abrasion, gagawan neng masanting para kareng aplikasyun na mangailangan masipit a pamagsara ampo ditak a pamag-maintain.

Key Structural Features

-

- Mumunang Eccentricity: Ingbalbulaing shaft maka offset ya keng libutad ning disc, babawasan na ing friction kabang magbukas/magsara ya ampo babawasan na ing wear kareng sealing surfaces.

- Kaduang Eccentricity: Ing shaft mas makarayu ya keng pipeline centerline, gagawang "wedging effect" na magpasanting keng pamag-seal kabang magsara ya ing disc.

- Pakinabang: Mamye yang masanting a pamag-seal at makaba ing bie ning serbisyu kumpara kareng single-eccentric o concentric a disenyu.

- Soft Sealing Mechanism

- Ing balbula gagamit yang malambut a sealing ring (keraklan gawa keng EPDM, NBR, o PTFE) a maka-embed keng katawan o disc ning balbula, para makasiguradung airtight ing pamagsara ampo compatibility kareng miyayaliwang media (alimbawa, danum, langis, gas, ampo non-abrasive fluids).

- Advantage: Mababa ing leakage rates (meeting API 598 o ISO 15848 standards) ampo minimal a torque a kailangan para keng operasyun.

- Dry Shaft Construction

- Ing shaft makasara ya keng media flow, para e na akit ing fluid. Ing disenyu ayni lalako nala deng posibling leakage paths keng shaft ampo babawasan na ing corrosion risks, lalu na keng agresibong kapaligiran.

- Key Component: Matas a kalidad a stem seals (alimbawa, V-type packing o mechanical seals) makasiguradung alang leakage keng shaft.

- Flange Connection

- Dinisenyu ya kareng standard a flange interfaces (eg, ANSI, DIN, JIS) para keng madaling pamag-install kareng pipeline. Ing flanged a disenyu mamye yang katatagan keng istruktura ampo magpasimple keng pamag-maintain.

Prinsipyu ning Pamagobra

- Pamuklat: Kabang mag-ikot ya ing baras, ingdouble-eccentricing disc kikimut ya ibat keng makasaradung posisyun, bagya-bagya yang makalako keng malambut a seal. Deng eccentric offsets babawasan da ing mumunang contact stress, gagawang masalese, mababang torque ing operasyun.

- Pamagsara: Ing disc mibabalik ya pabalik, at ing double-eccentric geometry gagawang progresibong sealing action. Ing wedging effect daragdagan na ing contact pressure pilatan ning disc ampo ing seal, para siguraduan ing masipit a pamagsara.

- Tandanan: Ing dry shaft design sisiguraduan na ing shaft e ya apektadu keng media temperature, pressure, o corrosiveness, a magpasanting keng kabilugan a reliability.

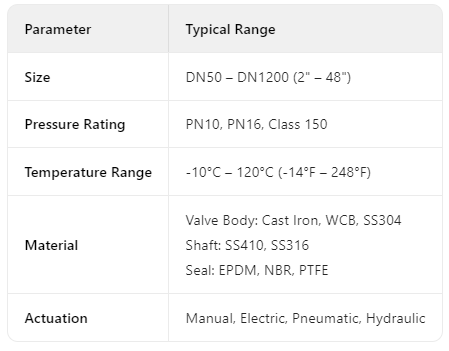

Technical Specifications

- Pamaglinis king Danum: Inuman a danum, wastewater, ampo sewage systems (mangailangan yang matas a sealing para keng hygienic standards).

- Chemical Industry: Corrosive fluids, acids, ampo alkalis (ing dry shaft protektan ne ing chemical attack).

- HVAC Systems: Air conditioning ampo heating pipelines (mababa torque para keng maralas a operasyun).

- Petrochemical & Oil/Gas: Non-abrasive media kalupa ning oil, gas, ampo solvents (mapanalig a pamagsara kareng kritikal a prosesu).

- Pamangan & Inuman: Sanitary applications (FDA-compliant seals siguraduan ing kaligtasan ning produktu).

-

bentahe kareng tradisyunal a balbula

- Superior Sealing: Deng malambut a seal makalako la keng leakage, masanting para kareng aplikasyun na mangailangan proteksyun keng kapaligiran o matas a kalinisan.

- Energy Efficiency: Ing mababang torque a operasyun babawasan na ing pamangailangan king actuation power, babawasan na ing gastus king operasyun.

- Makaba: Ing double-eccentric a disenyu babawasan na ing pangasira, kabang ing dry shaft protektan ne ing corrosion, a magpalwal king bie ning serbisyu.

- Makatipid keng espasyu: Compact a istruktura kumpara kareng gate o globe valves, masanting para kareng limitadu a espasyu.

Tips keng pamag-maintain ampo pamag-install

- Pamag-install: Siguraduan mung maka-align la reng flanges ampo deng bolts pare-pareu lang maka-tighten para aiwasan ing stress keng valve body.

- Maintenance: Regular meng inspeksyunan ing soft seal para keng wear at palitan nung masira ya. Lubricate me ing shaft ampo ing actuator pana-panaun para siguraduan ing masaleseng operasyun.

- Pamibili: Ibili keng tuyu, alang alikabuk a kapaligiran a ing balbula makabuklat yang bagya para mabawas ing stress keng seal.

Ing balbula ayni sasamut ne ing advanced engineering ampo ing praktikal a disenyu, mamye yang mapanalig ampo epektibung solusyun para kareng modernung industrial flow control a pamangailangan. Para keng partikular a pamag-customize (alimbawa, pamag-upgrade keng materyales o espesyal a coatings), pakisabi me ing manufacturer.

Oras ning pamagpost: Mayu-23-2025