- Pamili kareng Materyal

Low-End Valves

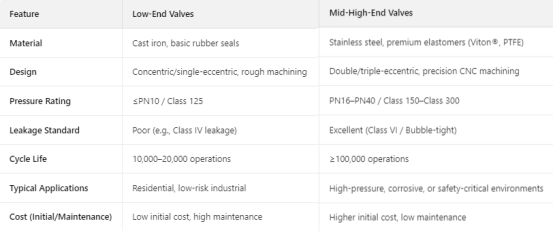

- Katawan/Disc Materials: Keraklan gagamit lang mababang metal kalupa ningcast irono unalloyed carbon steel, na malyaring alang corrosion resistance keng mabagsik a kapaligiran.

- Sealing Rings: Gawa keng basic elastomers antimo ingNR (natural rubber)o low-grade EPDM, a maki limitadu a chemical resistance ampo temperature tolerance (eg, ≤80°C / 176°F).

- baras: Maralas gagawan de ibat keng ordinaryung carbon steel a alang surface treatment, prone keng kalawang keng basa o acidic a kondisyun.

Mid-High-End Valves

- Katawan/Disc Materials: Gamitan la reng premium a materyales antimo ing stainless steel (SS304/316), ductile iron, o aluminum bronze para keng mas masanting a resistensya keng corrosion ampo mechanical strength.

- Sealing Rings: Gamitan la reng matas a performance a elastomer antimo ing FDA-compliant EPDM, NBR, PTFE, o Viton®,ain broader chemical compatibility (alimbawa, resistant kareng oils, acids, o solvents) ampo mas matas a temperatura (-20°C anggang 150°C / -4°F anggang 302°F).

- baras: Gawa ya keng stainless steel (SS410/316) a maki makinis o makabalut a babo (alimbawa, nickel plating) para aiwasan ing pangasira at pangatagas.

- Structural Design & Manufacturing

Low-End Valves

- Simpleng Disenyu: Basic concentric o single-eccentric structures na ating limitadu a sealing precision. Ing disc ampo ing luklukan malyari lang mika magaspang a makina, a magdalang mas matas a friction ampo torque.

- Pamanyiksik: Maralas mass-produced a alang ditak a kalidad a kontrol, a magresulta keng e pare-pareung tolerances. Deng leakage rates malyari lang e makatupad kareng mahigpit a pamantayan (alimbawa, lumampas kareng ANSI B16.104 Class VI requirements).

- Actuation:Keraklan makapares la kareng mura a manual a hawakan o basic a electric actuators, ala lang tibay para keng maralas a operasyun.

Mid-High-End Valves

- Advanced Design: Tandadouble-eccentric o triple-eccentric a istrukturapara mabawas ing friction, mas masanting ing pamag-seal, ampo mabawas ing wear. Alimbawa, deng double-eccentric a disenyu gagawang "wedging effect" para mas masipit a pamagsara.

- Precision Manufacturing: Machine ya keng high-precision CNC equipment, makasiguradung makinis ing kimut ning disc ampo ing masanting a seal contact. Ing leakage rates maralas makayabut ya o lalagpus ya keng ISO 15848-1 (eg, Bubble-tight Class A).

- Actuation: Compatible kareng premium actuators (pneumatic, hydraulic, o intelligent electric actuators) para kareng high-speed, high-cycle a aplikasyun. Deng mapilan a modelu atin lang positioners o feedback sensors para keng automation.

3. Performance & Reliability

Low-End Valves

- Pressure/Temperature Limits: Para kareng low-pressure a sistema (alimbawa, ≤PN10 / Class 125) ampo makitid a temperatura. Malyari yang mabigu keng high-pressure (eg, >PN16) o extreme temperature (-10°C anggang 90°C) a kapaligiran.

- Bie Serbisyu: Mepakuyad ya pauli ning e masanting a tibay ning materyales ampo ding depektu keng disenyu, mangailangan yang maralas a pamag-maintain o pamagpalit (alimbawa, 10,000-20,000 a siklo).

- Peligro ning Pamagtagas: Mas matas a chance ning seal deformation o shaft corrosion, a magdalang environmental leaks o system failures.

Mid-High-End Valves

- Pressure/Temperature Limits: Dinisenyu para kareng medium-to-high pressure systems (alimbawa, PN16–PN40 / Class 150–Class 300) ampo mas malawak a temperatura (-30°C anggang 200°C / -22°F anggang 392°F).

- Bie Serbisyu: Megawa ya para keng makabang panaun a kapanaligan, a maki cycle life a maygit 100,000 a operasyun. Deng mapilan a premium a modelu atin lang lifetime warranty.

- Pamagkontrol king Tagas: Deng advanced seals ampo anti-blowout shafts babawasan da ing leakage risks, gagawan dong masanting para kareng kritikal a aplikasyun antimo reng gas systems o hazardous fluid handling.

4. Aplikasyon

Low-End Valves

- Para kareng: E kritikal, mababa ing panganib a aplikasyun a maki basic a pamangailangan king pamagkontrol king danum, antimo:

- Sistema ning suplay ning danum keng tuknangan

- Simpleng HVAC ductwork

- Low-pressure irrigation o drainage

- Iwasan ing gamitan keng: High-pressure industrial pipelines, corrosive media, o safety-critical a kapaligiran (alimbawa, oil & gas, pharmaceuticals).

Mid-High-End Valves

- Masanting para kareng: Mangailangan a industrial ampo commercial a aplikasyun, kayabe na ing:

- Chemical processing plants (corrosive fluids)

- Pamangan at inuman (sanitary standards)

- Pamaglalang kuryenti (matas a temperaturang singaw)

- Oil & gas (explosion-proof requirements)

- Key Standards: Maralas sertipikadu la keng ISO, API, ASME, o ATEX para keng pamamintu kareng international safety ampo kalidad a regulasyun.

5. Gastus & Pamaningat

Low-End Valves

- mumunang gastus: Mas mura (20-50% mas ditak kesa kareng mid-high-end models), gagawan na lang maka-akit para kareng budget-sensitive a proyektu.

- Ayusan: Mas matas a gastus keng makabang panaun pauli ning maralas a pamagpalit seal, pamag-lubricate ning shaft, o pamag-ayus keng corrosion.

- Peligro ning Downtime: Mas prone kareng e asahan a kabiguan, a magdalang pangawala ning produksyun kareng industrial a setting.

Pamili keng ustung balbula (eg.TWS Valve)

- Low-End: Mayap ya para keng makuyad a panaun, e kritikal a gamit nung nukarin ing gastus ing mumunang bage.

- Mid-High-End: Mamuhunan ka kareti para keng reliability, safety, ampo long-term performance kareng masakit a aplikasyun. Parati mung isipan ing media type, operating conditions, ampo reng compliance requirements nung mamili kang valve.

Ing pamiyaliwa ayni papakit na nung bakit mid-high-end valvesD371X-16Qmas buri da reng industriya na mas mumuna ing kaligtasan ampo ing kahusayan, kabang deng low-end a opsyun magsilbi lang basic, cost-driven a pamangailangan.

malambut a tatak, masikan a pamagganapwafer butterfly valve, Double flange butterfly valve D34B1X-10Q, Gate valve, Y-strainer,Wafer dual plate check valve,-Megawa para kareng solusyun ning Leak Fredd. Masipit a Tatak, alang Kapantay a Kapanaligan, Ing kekang Ekspertu king Pamagkontrol king Daloy.

Oras ning pamagpost: Jun-07-2025